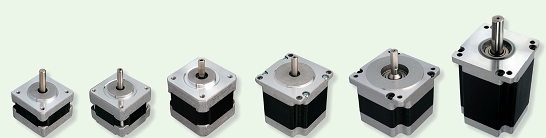

新闻:台江县非标设备专用步进电机42HS40-012A型录

减速机的正确使用

正确使用减速机,可以限度地避免零部件的损伤及损坏,保证稳定的噪声等级。减速机噪声会随负载的增加而增大,所以应在正常负载范围内使用。

定期维护与保养

定期的维护保养(换油,更换已磨损零部件,紧固件松动部件,清除内部杂物,齿轮箱清洗维护机利用齿轮箱原有的给排油系统和经过滤后的旧油可实现对齿轮箱的清洗、废油快速过滤、加注新油等功能,作业过程不改变硬件设施、不添加清洗剂,保证了齿轮箱安全运营,延长使用寿命。调整各部件间隙至标准规定值,检定各项几何精度等。)可以提高减速机抵抗噪声等级劣化能力,维持稳定的使用状态。

新闻:台江县非标设备专用步进电机42HS40-012A型录

CH400-3-S-G3-TL-H9CH400-5-S-G3-TL-H9CH400-10-S-G3-TL-H9CH400-15-S-G3-TL-H9CH400-20-S-G3-TL-H9CH400-25-S-G3-TL-H9CH400-30-S-G3-TL-H9CH400-40-S-G3-TL-H9CH400-45-S-G3-TL-H9CH400-50-S-G3-TL-H9CH400-60-S-G3-TL-H9CH400-70-S-G3-TL-H9CH400-80-S-G3-TL-H9CH400-90-S-G3-TL-H9CH400-100-S-G3-TL-H9CH400-120-S-G3-TL-H9CH400-140-S-G3-TL-H9CH400-160-S-G3-TL-H9CH400-180-S-G3-TL-H9CH400-200-S-G3-TL-H9CH750-3-S-G3-TL-H9CH750-5-S-G3-TL-H9CH750-10-S-G3-TL-H9CH750-15-S-G3-TL-H9CH750-20-S-G3-TL-H9CH750-25-S-G3-TL-H9CH750-30-S-G3-TL-H9CH750-40-S-G3-TL-H9CH750-45-S-G3-TL-H9CH750-50-S-G3-TL-H9CH750-60-S-G3-TL-H9CH750-70-S-G3-TL-H9CH750-80-S-G3-TL-H9CH750-90-S-G3-TL-H9CH750-100-S-G3-TL-H9CH750-120-S-G3-TL-H9CH750-140-S-G3-TL-H9CH750-160-S-G3-TL-H9CH750-180-S-G3-TL-H9CH750-200-S-G3-TL-H9CH1500-3-S-G3-TL-H9CH1500-5-S-G3-TL-H9CH1500-10-S-G3-TL-H9CH1500-15-S-G3-TL-H9CH1500-20-S-G3-TL-H9CH1500-25-S-G3-TL-H9CH1500-30-S-G3-TL-H9CH1500-40-S-G3-TL-H9CH1500-45-S-G3-TL-H9CH1500-50-S-G3-TL-H9CH1500-60-S-G3-TL-H9CH1500-70-S-G3-TL-H9CH1500-80-S-G3-TL-H9CH1500-90-S-G3-TL-H9CH1500-100-S-G3-TL-H9CH1500-120-S-G3-TL-H9CH1500-140-S-G3-TL-H9CH1500-160-S-G3-TL-H9CH1500-180-S-G3-TL-H9CH1500-200-S-G3-TL-H9CH2200-3-S-G3-TL-H9CH2200-5-S-G3-TL-H9CH2200-10-S-G3-TL-H9CH2200-15-S-G3-TL-H9CH2200-20-S-G3-TL-H9CH2200-25-S-G3-TL-H9CH2200-30-S-G3-TL-H9CH2200-40-S-G3-TL-H9CH2200-45-S-G3-TL-H9CH2200-50-S-G3-TL-H9CH2200-60-S-G3-TL-H9CH2200-70-S-G3-TL-H9CH2200-80-S-G3-TL-H9CH2200-90-S-G3-TL-H9CH2200-100-S-G3-TL-H9CH2200-120-S-G3-TL-H9CH2200-140-S-G3-TL-H9CH2200-160-S-G3-TL-H9CH2200-180-S-G3-TL-H9CH2200-200-S-G3-TL-H9

M16×1LH-6G表示细牙普通螺纹,公称直径16,螺距1,左旋,螺纹公差带中径、大径均为6G,旋合长度按中等长度考虑。外六角螺栓的等级外六角螺栓标准有一个标准是级别标准,级别标准分为4.8级和8.8级。市场上这两个级别用的多。是4.8级外六角螺栓。因为它比8.8级外六角螺栓更的多。用到当然就更广泛些。但对于要求高的产品来说。因其硬度等各方面的高要求。这就得用到8.8级的外六角螺栓。外六角螺栓从硬度和螺丝扭力等方面来说更加硬。

蜗轮减速马达的保养方法:

1、不得重力捶击蜗轮减速马达外壳,以免损坏。

2、定期检查安装基础,密封件,传动轴等是否正常。若产生不正常现象,应立即停机检查,排除故障。

3、应尽量避免减速机受阳光直射和处于恶劣条件下。

4、应担供良好的通风条件确保减速机正常散热。

5、使用推荐使用的润滑油。

以上方法在一定程度上能够延长蜗轮减速马达的使用寿命!

新闻:台江县非标设备专用步进电机42HS40-012A型录

CH750-3-S-B-G4-DL-H0CH750-5-S-B-G4-DL-H0CH750-10-S-B-G4-DL-H0CH750-15-S-B-G4-DL-H0CH750-20-S-B-G4-DL-H0CH750-25-S-B-G4-DL-H0CH750-30-S-B-G4-DL-H0CH750-40-S-B-G4-DL-H0CH750-45-S-B-G4-DL-H0CH750-50-S-B-G4-DL-H0CH750-60-S-B-G4-DL-H0CH750-70-S-B-G4-DL-H0CH750-80-S-B-G4-DL-H0CH750-90-S-B-G4-DL-H0CH750-100-S-B-G4-DL-H0CH750-120-S-B-G4-DL-H0CH750-140-S-B-G4-DL-H0CH750-160-S-B-G4-DL-H0CH750-180-S-B-G4-DL-H0CH750-200-S-B-G4-DL-H0CH1500-3-S-B-G4-DL-H0CH1500-5-S-B-G4-DL-H0CH1500-10-S-B-G4-DL-H0CH1500-15-S-B-G4-DL-H0CH1500-20-S-B-G4-DL-H0CH1500-25-S-B-G4-DL-H0CH1500-30-S-B-G4-DL-H0CH1500-40-S-B-G4-DL-H0CH1500-45-S-B-G4-DL-H0CH1500-50-S-B-G4-DL-H0CH1500-60-S-B-G4-DL-H0CH1500-70-S-B-G4-DL-H0CH1500-80-S-B-G4-DL-H0CH1500-90-S-B-G4-DL-H0CH1500-100-S-B-G4-DL-H0CH1500-120-S-B-G4-DL-H0CH1500-140-S-B-G4-DL-H0CH1500-160-S-B-G4-DL-H0CH1500-180-S-B-G4-DL-H0CH1500-200-S-B-G4-DL-H0CH2200-3-S-B-G4-DL-H0CH2200-5-S-B-G4-DL-H0CH2200-10-S-B-G4-DL-H0CH2200-15-S-B-G4-DL-H0CH2200-20-S-B-G4-DL-H0CH2200-25-S-B-G4-DL-H0CH2200-30-S-B-G4-DL-H0CH2200-40-S-B-G4-DL-H0CH2200-45-S-B-G4-DL-H0CH2200-50-S-B-G4-DL-H0CH2200-60-S-B-G4-DL-H0CH2200-70-S-B-G4-DL-H0CH2200-80-S-B-G4-DL-H0CH2200-90-S-B-G4-DL-H0CH2200-100-S-B-G4-DL-H0CH2200-120-S-B-G4-DL-H0CH2200-140-S-B-G4-DL-H0CH2200-160-S-B-G4-DL-H0CH2200-180-S-B-G4-DL-H0CH2200-200-S-B-G4-DL-H0CH3700-3-S-B-G4-DL-H0CH3700-5-S-B-G4-DL-H0CH3700-10-S-B-G4-DL-H0CH3700-15-S-B-G4-DL-H0CH3700-20-S-B-G4-DL-H0CH3700-25-S-B-G4-DL-H0CH3700-30-S-B-G4-DL-H0CH3700-40-S-B-G4-DL-H0CH3700-45-S-B-G4-DL-H0CH3700-50-S-B-G4-DL-H0CH3700-60-S-B-G4-DL-H0CH3700-70-S-B-G4-DL-H0CH3700-80-S-B-G4-DL-H0CH3700-90-S-B-G4-DL-H0CH3700-100-S-B-G4-DL-H0CH3700-120-S-B-G4-DL-H0CH3700-140-S-B-G4-DL-H0CH3700-160-S-B-G4-DL-H0CH3700-180-S-B-G4-DL-H0CH3700-200-S-B-G4-DL-H0

为了保证轴承安装后的滚道变形小,过盈配合的过盈量不能取得太大,而高速下的离心力和高温下的热膨胀,或是抵销配合表面的法向压力。或是使配合面松弛,因此过盈量必须在考虑上述两种因素的前提下审慎地加以计算,在常温常速下有效的过盈量对于高速轴承可能是无效的。如果计算结果这个矛盾太大(通常只有在超高速下才有这种情况),只有采取环下润滑法与静压润滑法并用的双重润滑措施,而这种方案有可能使轴承的dmn值突破3万的大关。

新闻:台江县非标设备专用步进电机42HS40-012A型录