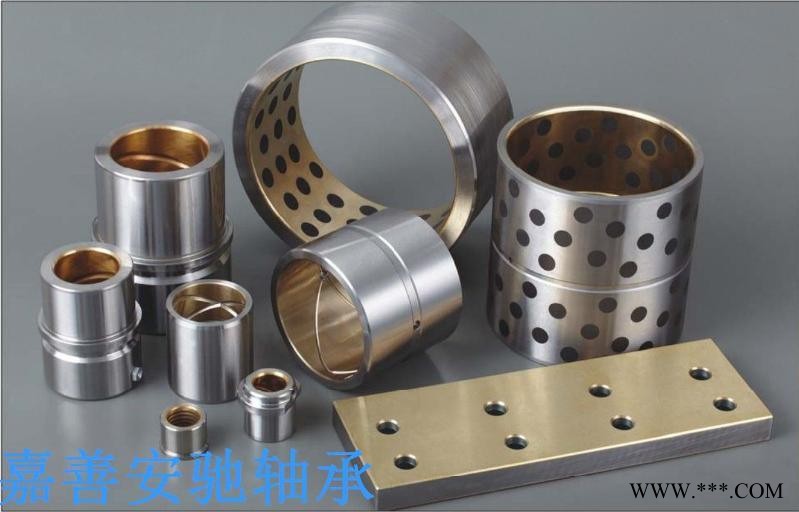

轴承;滑动轴承;通用零部件

普通会员

产品价格面议

产品品牌未填

最小起订未填

供货总量未填

发货期限自买家付款之日起 天内发货

浏览次数779

企业旺铺https://www.qqdj.wang/index.php?homepage=shc105

更新日期2022-12-02 02:32

品牌: |

未填 |

所在地: |

浙江 嘉兴市 |

起订: |

未填 |

供货总量: |

未填 |

有效期至: |

长期有效 |

本网页所展示的有关【双金属铜套, 内径50轴承库存, 轴承外径60_推力球轴承_嘉善安驰轴承制造有限公司】的信息/图片/参数等由全球电机网的会员【嘉善安驰轴承制造有限公司】提供,由全球电机网会员【嘉善安驰轴承制造有限公司】自行对信息/图片/参数等的真实性、准确性和合法性负责,本平台(本网站)仅提供展示服务,请谨慎交易,因交易而产生的法律关系及法律纠纷由您自行协商解决,本平台(本网站)对此不承担任何责任。您在本网页可以浏览【双金属铜套, 内径50轴承库存, 轴承外径60_推力球轴承_嘉善安驰轴承制造有限公司】有关的信息/图片/价格等及提供【双金属铜套, 内径50轴承库存, 轴承外径60_推力球轴承_嘉善安驰轴承制造有限公司】的商家公司简介、联系方式等信息。

在您的合法权益受到侵害时,欢迎您向邮箱发送邮件,或者进入《网站意见反馈》了解投诉处理流程,我们将竭诚为您服务,感谢您对全球电机网的关注与支持!